Shoe Technology

Our goal at Sutton’s is to provide you with the latest technology in Safety Footwear. With over 25 brands in stock, Sutton’s gives you access to the newest footwear technology allowing for maximum comfort and safety on your job site. Safety Footwear Technology can be broken down into three categories: Protection Technology, Comfort Technology, and Performance Technology.

Protection Technology:

- Safety Toe Types

- Steel Toe: The original type of safety toe, Steel Toes have been providing protection in the industrial industry for over 80 years.

- Alloy Toe: Made from lightweight material such as titanium, aluminum , etc., Alloy Toes provide protection while being thinner and lighter than steel toe, similar in weight to Composite Toes, and allowing for more toe room.

- Composite Toe: Lighter weight than their steel toe counterparts, Composite Toes provide protection without conducting heat, electrical charges, or cold. Composite Toes can be made from different non-metallic materials such as carbon fiber, plastic, fiber glass, or Kevlar.

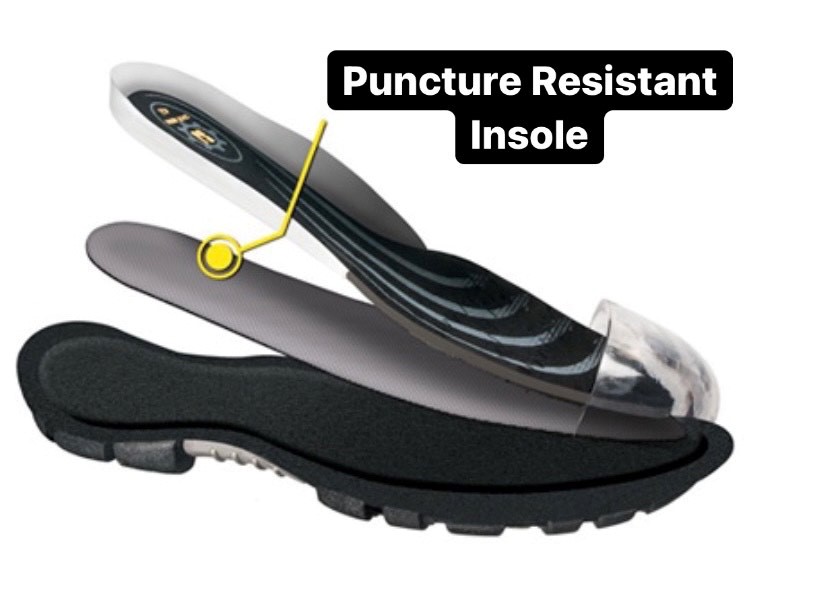

- Puncture Resistance: Puncture resistant footwear provides protection against sharp objects often found on the floor of a work place. This type of technology includes a steel or composite plate that is positioned within the midsole to protect you from the dangers of stepping on objects such as nails or screws.

- Sutton’s provides puncture resistant insoles (Kevlar, etc.) that can be placed underneath the insole of any shoe to make the shoe puncture resistant by OSHA standards.

- Slip Resistance: The soles of slip resistant shoes reduce the slickness of surfaces that could cause a fall or accident. Slip resistant outsoles use materials and surface patterns to maximize the grip of your shoe against wet and oily surfaces.

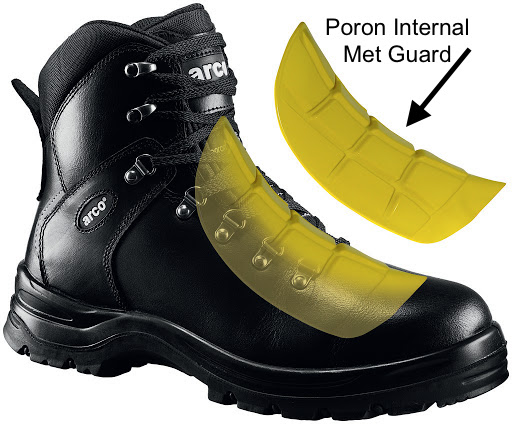

- Metatarsal Protection: Metatarsal guards protect the top of the foot from injuries sustained by heavy items falling, dropping, or rolling onto the top of the foot. Metatarsal guards can be internal or external, and made out of rigid plastics, rubber, and hinged or solid metal.

- Poron Metatarsal Guards : Different from the stiff and rigid plates used by other metatarsal guards, Poron Metatarsal Guards are made of poron, an open cell foam, that aids in the protection of the top of your foot by dispersing energy when a heavy item is dropped on it. This type of guard allows more flexibility and comfort for your shoe.

Comfort Technology:

- Anti Fatigue: Anti-Fatigue Technology is found in many types of safety footwear. It functions similarly to anti-fatigue floor mats found in work stations where employees must stand on their feet constantly. This type of technology is often found within insoles such as those in the Timberland Pro Series, and contain inverted cone foam that is designed to absorb shock and return energy to your feet.

- Foot Beds: There are three different classifications of foot beds in terms of foot arches: High Arch, Medium Arch, and Low Arch. While most shoes contain medium arches, all of Sutton’s footwear have removable insoles so that insoles can be changed to better meet your shoe needs.

- Insoles: Removable insoles allow for the accommodation of individual footwear needs. Sutton’s does this by providing a variety of replacement insoles, so that you can have the most comfortable safety footwear.

- Ener-Gel: Sutton’s provides Ener-Gel insoles that aid in comfort, shock absorption, and foot pain relief. This type of insole has high rebound foam for maximum cushioning and energy return, with a flexible arch support.

- Timberland Pro Anti-Fatigue Insoles: Although many Timberland Pro safety shoes include this type of insole, Sutton’s provide replacement insoles by Timberland for you to add to any type of shoe.

- MEGAComfort: Sutton’s now provides MEGAComfort insoles that aids in maximum comfort, shock absorption, and is ergonomically designed by doctors. This insole is a cost-effective option to increase employee safety and health.

- Outsoles: Several types of outsoles are found in safety shoes to provide different types of protection and comfort. One of the most popular types of outsoles is a duel density outsole, which contains two separate layers. The outer layer is harder and made of rubber to provide durability and slip resistance. The inner layer is made of polyurethane or similar materials to add cushioning. Outsoles often contain different compositions in areas of the shoe in order to make them more flexible across the ball of your foot.

- Uppers: The “upper” of a shoe is the material that covers all outside portions of the shoe. Everything you see by looking straight down at your shoes can be considered the “upper”. This outer portion can be made of leather, synthetic leather, or mesh.

- Leather: The most predominant material for safety shoe “uppers”, leather provides durability, breathability, and moisture wicking capabilities that are beneficial to those working in hot conditions.

- Synthetic Leather: Manufactured leather is used most commonly on shoes that require extra abrasion resistance, chemical resistance, and water-proofing capabilities.

- Mesh: Mesh “uppers” provide the most movement and flexibility for your feet, as well as being beneficial to those working in a hot environment by providing enhanced breathability.

Performance Technology:

- Waterproof: Waterproofing capabilities help to seal the surface of the shoe to keep water from penetrating the shoe. This type of technology provides a high level of protection against water even under tough conditions. Types of water proofing include Gortex, Drylex, and other water proofing membranes.

- Water Resistant: Water Resistant footwear allows for the resisting of water for an extended period of time. This provides protection from water when the shoe comes in contact with it on the surface.

- Abrasion Resistance: Safety footwear is made abrasion resistant through the use synthetic leather or an added coating to conventional leather. This technology helps to prevent cutting of shoes as well as over all wear-and-tear.

- Stability: The stability of safety footwear is often increased through the use of a heel counter and strategically placed layers of leather that add to the overall stability of the shoe.

- Heel Counter: Often made of plastic or other hard materials, Heel counters add stability to your foot by aiding in the prevention of rolling ankles and providing support for those often climbing up and down ladders or stairs.

- Lining: Linings in the inner portion of shoes are used to aid in water proofing and insulation.

- Waterproofing Liners: This type of liner including Gortex, Drylex, and other water proofing membranes aids in keeping water out, keeping sweat away from the foot until the shoe is removed, and allows for more breathability.

- Thinsulate: A type of insulating liner, Thinsulate helps to trap in heat while still allowing moisture to escape. Both warm and light weight, Thinsulate is can also be made water resistant through the use of hydrophobic fibers, keeping your feet both warm and dry.